Hard alloy is an alloy made by powder metallurgy with one or several refractory carbides (tungsten carbide, titanium carbide, etc.) as the main component, and metal powders (cobalt, nickel, etc.) added as adhesives. It is mainly used for manufacturing high-speed cutting tools and cutting tools for h

Read More

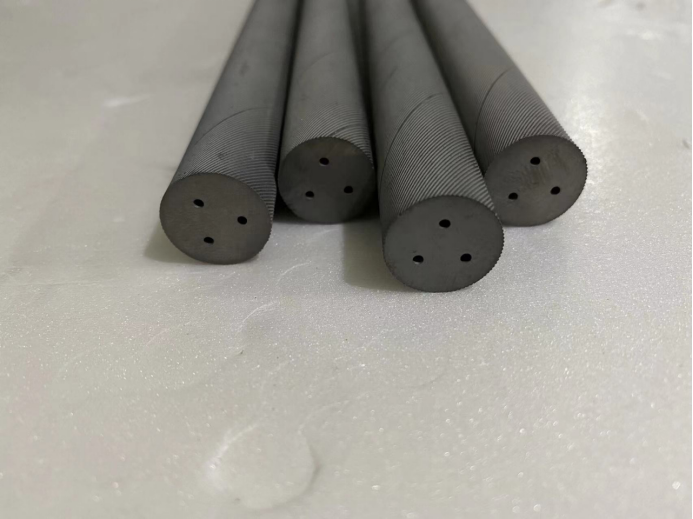

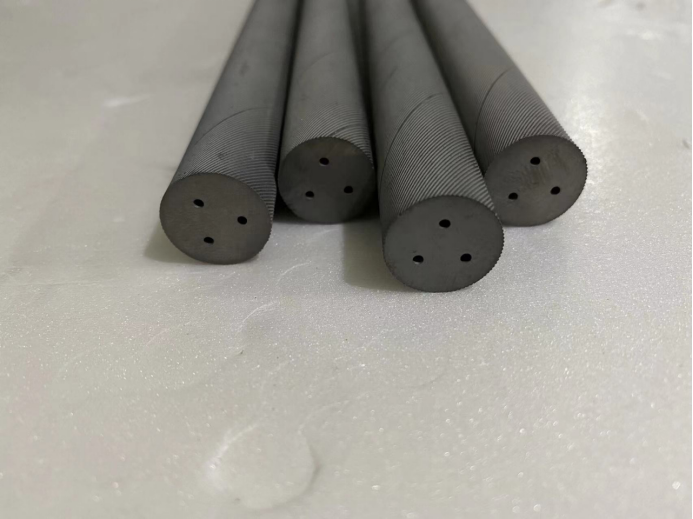

Tungsten carbide round rod is a composite material produced by powder metallurgy, consisting of refractory metal compounds (hard phases) and bonding metals (bonding phases). Tungsten carbide is a different local term.

Read More

In order to achieve better quality cutting and maximize tool life, we need to inspect the blades after machining, summarize the causes of different forms of blade wear, and find solutions, which are the foundation of successful milling.Rear blade wear 1Rapid wear leading to poor surface quality or e

Read More

1. Application:This broaching machine adopts external removing Chip method.This machine is suitable for column material,with workpiece rotating, cutting tool feeding.Hole diameter:φ5mm~φ50mmMax hole depth:1500mmCNC system:Simens 828D2. AccuracyHole accuracy:IT7~IT113. Description of workpiece proces

Read More

Quenching and tempering: The heat treatment method of high-temperature tempering after quenching is called quenching and tempering. High temperature tempering refers to tempering between 500 and 650 ℃. Quenching and tempering can greatly adjust the properties and materials of steel, with good streng

Read More