Deep hole drilling is the process frequently used for initial hole generation in large-scale industrial parts. When combined with Drillstar’s industry-leading bore finishing operations, deep hole drilling delivers exemplary levels of precision and efficiency to a wide variety of manufacturing applic

Read More

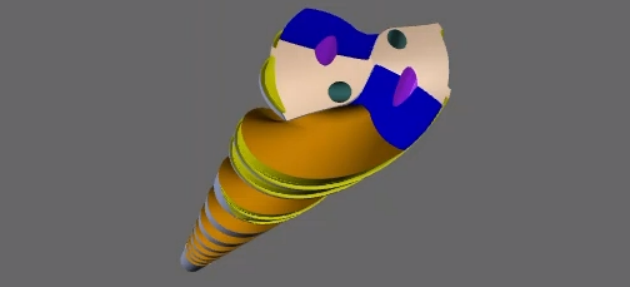

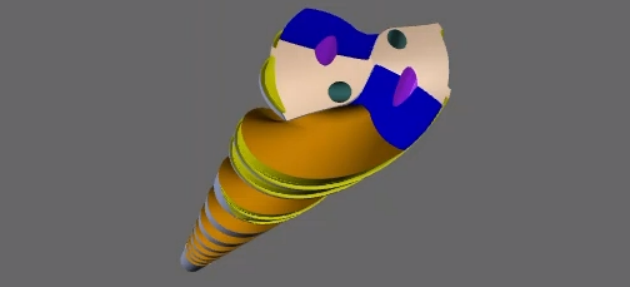

Today, Drillstar will introduce the detection of coolant holes and other characteristics of coolant holes. Firstly, you may notice that the drill bit backlash and cooling holes are not completely aligned. This is because we did not separate the drill bit from the coolant hole.

Read More

In the process of mechanical machining, the machining of holes has always been a key and difficult point in the entire machining engineering. Usually, drilling tools such as drills, drill chucks, reamers, honing rods, etc. are used. Floating fixtures are generally not mentioned in the industry, but

Read More

Thermal deformation is one of the reasons that affects machining accuracy. Drillstar Machines are affected by changes in workshop environment temperature, electric motor heating, mechanical motion friction heating, cutting heat, and cooling media, resulting in uneven temperature rise in various par

Read More

The processing characteristics of deep hole drills: 1. The Drillstar tool holder is limited by the aperture, with a small diameter and a large length, resulting in poor rigidity and low strength. It is prone to vibration, ripples, and taper during cutting, which affects the straightness and surfac

Read More