DRILLSTAR CARBIDE TOOLS ARE WORKING IN MANY PLACES AROUND THE WORLD

| Availability: | |

|---|---|

| Quantity: | |

Drillstar ’s brazed single flute gun drills have following properties:

Diameter range: 3 – 40mm

Overall length: 5000mm (maximum)

Single fluted type is the most common type. And the most widely used.

Contains one-piece carbide drill bit and steel drill bit with carbide inserts.

The tube and shank are made of steel material. And through heat treatment.

The three parts are brazed to be a complete tool.

Drillstar sells gun drills in diameter ranges from 1.40 mm to 50.80 mm (0.055″ to 2.0″). Also, we offer a wide variety of gundrill types such as:

Solid carbide tip & shank, single kidney oil hole, single flute

Single round oil hole, single flute

Two round oil holes, single flute

Kidney shaped oil hole, single flute

Two oil holes, two flute

Single oil hole, single flute, chips ahead reamer

Two oil holes, two flute, chips ahead reamer

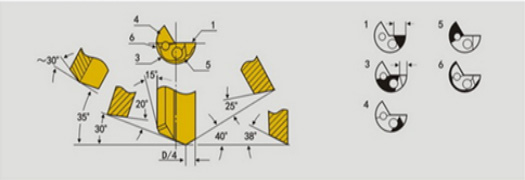

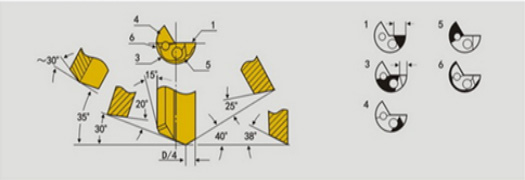

The rated grinding angle fits for drilling of the most of material. After using, through re-grinding can prolong the service life.

1 All carbide tips are from European carbide manufacturers ESTECH and Ceratizit, with which guarantees the quality of the tools. The suppliers also provide the materials to Boteck and TBT.

2. Stable quality which are testimofied by clients around the clients.

3. Fast delivery: We can delivery with 7 days for general quantity while EU and USA factory usually spend 1 month.

Diameter≤5.00mm(standard grinding angle for single blade gun drill with diameter no more than 5.00mm.)

Diameter 5.00~20.00mm(Standard grinding angle for single blade gun drill with diameter no more between 5.00mm and 20.00mm)

3.Diameter≥20.00mm( standard grinding angle for single-blade gun drill with diameter over 20.00mm)

PS: We can adjust the angles according to the material being drilled and accuracy requirements.

Clamping sleeves

In addition to manufacturing below standard clamping sleeves, Drillstar also customizes clamping to your special requirements (from a diagram or sample)

Material | Cutting force | Hardness | cutting speed | gun drill diameter(mm) | ||||

N/mm3 | HB | V.m/min | 0.98-3.00 | 3.00-6.30 | 6.00-12.50 | 12.50-40.50 | ||

Feeding rate,fm mm/r | ||||||||

Non alloy | non hardened 0.1-0.25% | 2000 | 90-200 | 60-120 | 0.003-0.010 | 0.005-0.003 | 0.015-0.055 | 0.020-0.110 |

non hardened 0.25-0.55% | 2100 | 50-120 | 0.003-0.010 | 0.005-0.003 | 0.015-0.055 | 0.020-0.110 | ||

non hardened 0.55-0.8% | 2180 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 | |

Low alloy | non hardened | 2100 | 150-260 | 40-120 | 0.003-0.010 | 0.004-0.030 | 0.010-0.055 | 0.020-0.110 |

hardened and fixed | 2775 | 220-450 | 40-120 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 | |

high alloy | annealing | 2500 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 |

hardened tool steel | 3750 | 250-350 | 50-100 | 0.003-0.010 | 0.006-0.025 | 0.015-0.060 | 0.030-0.100 | |

High cast steel | non alloy | 1800 | 90-225 | 50-120 | 0.003-0.010 | 0.006-0.030 | 0.015-0.055 | 0.020-0.110 |

low alloy(alloy <5%) | 2100 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.050 | 0.020-0.100 | |

rolled/forged | ferrite、martensite、non hardened | 2300 | 150-270 | 40-90 | 0.003-0.008 | 0.004-0.025 | 0.010-0.040 | 0.020-0.100 |

rolled/forged | aussenite | 2600 | 150-275 | 40-90 | 0.003-0.008 | 0.004-0.025 | 0.010-0.040 | 0.020-0.100 |

malleable cast-iron | ferrite | 960 | 110-145 | 70-90 | 0.005-0.010 | 0.008-0.030 | 0.020-0.070 | 0.050-0.190 |

pearlite | 1100 | 150-270 | 60-90 | 0.005-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 | |

grey cast iron | low tensile strength | 1100 | 150-220 | 60-90 | 0.004-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 |

high tensile strenght | 1290 | 200-330 | 15-90 | 0.003-0.010 | 0.003-0.030 | 0.005-0.070 | 0.010-0.190 | |

nodular cast iron | ferrite | 1050 | 125-230 | 70-90 | 0.005-0.010 | 0.008-0.030 | 0.020-0.070 | 0.050-0.190 |

pearlite | 1760 | 200-300 | 60-90 | 0.004-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 | |

AL alloy | cast.non aging | 750 | 40-100 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 |

Copper and copper alloy | pb>1% free cutting alloy pb>1% | 700 | 70-160 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 |

copper and copper with lead pb<1% | 700 | 50-200 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 | |

Drillstar ’s brazed single flute gun drills have following properties:

Diameter range: 3 – 40mm

Overall length: 5000mm (maximum)

Single fluted type is the most common type. And the most widely used.

Contains one-piece carbide drill bit and steel drill bit with carbide inserts.

The tube and shank are made of steel material. And through heat treatment.

The three parts are brazed to be a complete tool.

Drillstar sells gun drills in diameter ranges from 1.40 mm to 50.80 mm (0.055″ to 2.0″). Also, we offer a wide variety of gundrill types such as:

Solid carbide tip & shank, single kidney oil hole, single flute

Single round oil hole, single flute

Two round oil holes, single flute

Kidney shaped oil hole, single flute

Two oil holes, two flute

Single oil hole, single flute, chips ahead reamer

Two oil holes, two flute, chips ahead reamer

The rated grinding angle fits for drilling of the most of material. After using, through re-grinding can prolong the service life.

1 All carbide tips are from European carbide manufacturers ESTECH and Ceratizit, with which guarantees the quality of the tools. The suppliers also provide the materials to Boteck and TBT.

2. Stable quality which are testimofied by clients around the clients.

3. Fast delivery: We can delivery with 7 days for general quantity while EU and USA factory usually spend 1 month.

Diameter≤5.00mm(standard grinding angle for single blade gun drill with diameter no more than 5.00mm.)

Diameter 5.00~20.00mm(Standard grinding angle for single blade gun drill with diameter no more between 5.00mm and 20.00mm)

3.Diameter≥20.00mm( standard grinding angle for single-blade gun drill with diameter over 20.00mm)

PS: We can adjust the angles according to the material being drilled and accuracy requirements.

Clamping sleeves

In addition to manufacturing below standard clamping sleeves, Drillstar also customizes clamping to your special requirements (from a diagram or sample)

Material | Cutting force | Hardness | cutting speed | gun drill diameter(mm) | ||||

N/mm3 | HB | V.m/min | 0.98-3.00 | 3.00-6.30 | 6.00-12.50 | 12.50-40.50 | ||

Feeding rate,fm mm/r | ||||||||

Non alloy | non hardened 0.1-0.25% | 2000 | 90-200 | 60-120 | 0.003-0.010 | 0.005-0.003 | 0.015-0.055 | 0.020-0.110 |

non hardened 0.25-0.55% | 2100 | 50-120 | 0.003-0.010 | 0.005-0.003 | 0.015-0.055 | 0.020-0.110 | ||

non hardened 0.55-0.8% | 2180 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 | |

Low alloy | non hardened | 2100 | 150-260 | 40-120 | 0.003-0.010 | 0.004-0.030 | 0.010-0.055 | 0.020-0.110 |

hardened and fixed | 2775 | 220-450 | 40-120 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 | |

high alloy | annealing | 2500 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.060 | 0.020-0.100 |

hardened tool steel | 3750 | 250-350 | 50-100 | 0.003-0.010 | 0.006-0.025 | 0.015-0.060 | 0.030-0.100 | |

High cast steel | non alloy | 1800 | 90-225 | 50-120 | 0.003-0.010 | 0.006-0.030 | 0.015-0.055 | 0.020-0.110 |

low alloy(alloy <5%) | 2100 | 150-250 | 40-100 | 0.003-0.010 | 0.004-0.025 | 0.010-0.050 | 0.020-0.100 | |

rolled/forged | ferrite、martensite、non hardened | 2300 | 150-270 | 40-90 | 0.003-0.008 | 0.004-0.025 | 0.010-0.040 | 0.020-0.100 |

rolled/forged | aussenite | 2600 | 150-275 | 40-90 | 0.003-0.008 | 0.004-0.025 | 0.010-0.040 | 0.020-0.100 |

malleable cast-iron | ferrite | 960 | 110-145 | 70-90 | 0.005-0.010 | 0.008-0.030 | 0.020-0.070 | 0.050-0.190 |

pearlite | 1100 | 150-270 | 60-90 | 0.005-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 | |

grey cast iron | low tensile strength | 1100 | 150-220 | 60-90 | 0.004-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 |

high tensile strenght | 1290 | 200-330 | 15-90 | 0.003-0.010 | 0.003-0.030 | 0.005-0.070 | 0.010-0.190 | |

nodular cast iron | ferrite | 1050 | 125-230 | 70-90 | 0.005-0.010 | 0.008-0.030 | 0.020-0.070 | 0.050-0.190 |

pearlite | 1760 | 200-300 | 60-90 | 0.004-0.010 | 0.006-0.030 | 0.010-0.070 | 0.030-0.190 | |

AL alloy | cast.non aging | 750 | 40-100 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 |

Copper and copper alloy | pb>1% free cutting alloy pb>1% | 700 | 70-160 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 |

copper and copper with lead pb<1% | 700 | 50-200 | 65-300 | 0.005-0.015 | 0.006-0.040 | 0.020-0.070 | 0.030-0.150 | |

Carbide Tools Solution Specialist-Drillstar